Design and cleanability

Essential yet state-of-the-art autoclave design combines aesthetics with practicality. All surfaces ensure the highest degree of sanitisation while the glass touchscreen combines maximum hygiene with outstanding functionality. Style and practicality, to deliver a cutting-edge sterilization experience.

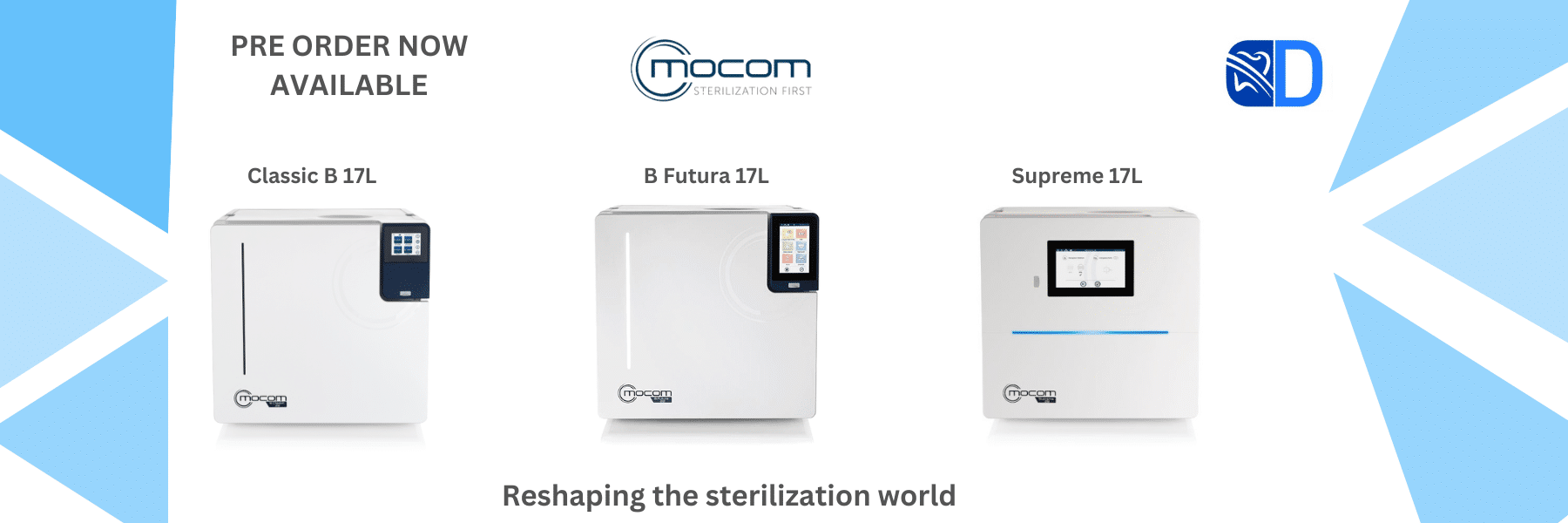

Three volumes, one size

The available volumes are 17, 22 and 28 litres. Three different capacities let users select the machine that best suits their needs. The external dimensions – identical on all three machines – make installation easy, even when recessed, minimising the space occupied on worktops.

Load versability

The 17 and 22-litre models are supplied with five trays and can house up to three drawers. The 28-litre version is supplied with six trays and can house up to four drawers. Loading is made even more versatile by the Modular Tray Holder, an optional accessory that maximises configurability.

B Classic

Versatile solution:

effective and essential

User-friendly display

The 3.2’’ touchscreen ensures effective, intuitive control, allowing users to run the entire sterilization process with the utmost simplicity. Clear and simple graphics make it easy to use the various functions, smoothing every single step.

Download of cycle reports

Cycle reports are generated at the end of each cycle and automatically saved on the autoclave memory. Up to 10,000 cycles can be saved. These can be downloaded in PDF format using the USB port on the front of the machine. The DataSter software supplied with the machine allows direct automatic downloading of reports to a network or PC folder.

EasyCheck – an optional in-Cloud platform that delivers remote technical support to reduce service times significantly – guarantees efficiency and reliability. Software updates, maintenance interval checks, remote verification of components and sensors, etc. EasyCheck ensures long-lasting autoclave performance.

Traceability software

MyTrace is an optional software for autoclaves. Installable on a practice PC, it’s used to associate sterilized instrument sets with patients via a barcode. A cycle archive, a patient list and sterile instrument association make MyTrace an irreplaceable tool for completing the traceability process and ensuring legal protection for the dentist.

Printer

To complete the range, an optional external printer for producing reports or barcode labels is available. A useful tool that completes the traceability process and allows pairing of sterilization cycle and sterile instruments.

Conductivity sensor

The in-tank sensor checks water quality to ensure a correct and long-lasting machine operation.

Custom cycle

The autoclave has a customisable cycle that lets operators safely adapt the sterilization cycle to the specific needs of the dental practice. By selecting from a pre-set range of legally compliant values, a custom cycle can be set up to optimise the process, ensuring the flexibility and precision needed to meet the requirements of different working conditions.

Delayed start and extra drying

The delayed start option lets users program cycle start times to rationalise the way the machine is used.

The extra drying function lets users set customised drying times to cope with difficult loads.

Test and maintenance reminder

It is also possible to activate reminders to perform routine tests.

These notify the operator of the need to perform periodic sterilizer tests: Vacuum Test and Helix – Bowie & Dick Test.

At the same time, maintenance deadline warnings will be displayed to maximise device efficiency and operability.

Touchscreen and Video Tutorial

The 5’’ touchscreen streamlines day-to-day use of the sterilizer through quick responsiveness to commands and user-friendly organisation of all the functions. The high-performance display can also be used to view video tutorials, providing a clear visual guide on how to use the sterilizer correctly. To make the most of sterilizer performance, users can also consult the manual at any time.

Cycle time and Modular Drying

This autoclave meets the needs of even the most demanding users. Combining reliable high-performance internal components with a control system that optimises each phase reduces sterilization cycle times. The exclusive Modular Drying function lets users select the load quantity to be sterilized. This adapts the duration of the drying phase, thus shortening cycle times. A complete B cycle in just 31 minutes.

Light communication

The device also communicates using light. The LED bar incorporated in the door provides immediate information on machine status by varying the light pulses according to the phase of operation. Consequently, users can see which phase of the process the autoclave is performing at a glance, even from some distance away

Water management

The integrated demineralizing filter lets you supply the sterilizer with normal mains water without any need for external treatment devices. The main advantages: rationalised spaces, streamlined processes, significant savings. Sensors monitor the quality of the demineralized water provided by the integrated filter. Users receive messages on filter status, ensuring autoclave efficiency at all times.

Video tutorial, on-display info

High-resolution images make the 7’’ display a valuable tool for all users. Simple video tutorials provide important use and maintenance instructions. A full complement of information – from indications on load positioning to instructions for periodic maintenance – is readily accessible on the machine. What’s more, cycle reports saved on the autoclave memory can be viewed on the screen.

Light communication

The device also communicates using light. The LED bar incorporated in the door provides immediate information on machine status by varying the colours according to the phase of operation. Consequently, users can see which phase of the process the autoclave is performing at a glance, even from some distance away.

NFC – Near Field Communication

The NFC sensor simplifies the assistant’s workflow. Activating user ID ensures only authorised personnel can access the machine functions. To activate, simply bring the NFC card, supplied with the sterilizer and associated with the user, up to the machine.

Water quality control

The built-in conductivity sensor ensures compliance with water quality parameters, protecting the internal components of the device. It also monitors the status of the filtration system. Clear messages on the display inform the user when the filters need replacing.

Integrated demineralization

A demineralization filter housed in the main tank lets users fill the reservoir with ordinary mains water, resulting in excellent rationalisation of the available space, streamlined processes and significant savings. Moreover, the filtration system delivers never-before-seen operational simplicity. To make water management even easier, optional automatic filling systems are available.

Treating used water

The recirculation filter incorporated in the secondary reservoir allows used water to be demineralized and purified. This process makes it reusable in subsequent sterilization cycles and automatically controls the water delivery reservoir. Just 5 litres of mains water is needed to perform 50 sterilization cycles: a market-leading specific consumption of just 100 ml/cycle.